Modern textile technology has revolutionized the way we treat denim.

Automated systems now handle everything from fabric distressing to color fading with precision.

Workers use advanced machinery to mold denim onto specialized forms, preparing them for laser treatments that create the trendy worn look with minimal manual effort.

Laser Precision: The Future of Fabric Customization

Laser cutting and engraving are now staples in fabric processing.

High-powered lasers can cut patterns or distress jeans with pinpoint accuracy, reducing waste and increasing efficiency.

The result? Perfectly styled garments ready for retail, with significantly less human labor involved.

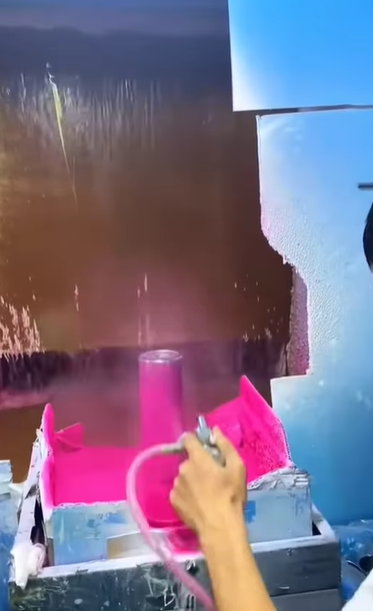

Spray-Painting Innovation: Fast Customization in Vibrant Colors

Technology has made it easy to add vibrant colors to products.

Automated spray booths can coat items like containers or industrial parts in any color desired, ensuring even application and quick drying times.

This system not only speeds up production but also allows for high-volume customization.

Bottle Formation: Molding Plastic with Precision

Plastic containers are produced with high-tech molding machines that shape, cool, and solidify products in seconds.

Heated plastic is injected into molds, rapidly forming bottles or other containers with consistent quality, ready for labeling and filling.

Packaging Perfection: Automation in Every Fold

Modern packaging machines take raw materials and convert them into neatly packed products in one seamless process.

Whether it’s wrapping tissues or bagging snacks, these systems ensure everything is sealed, labeled, and ready for shelves at lightning speed.

Streamlined Dish Production: Plates and Bowls on the Move

In ceramics, automation lines handle the delicate task of forming, glazing, and stacking plates and bowls.

These machines maintain consistency in shape and design, significantly reducing the time and effort traditionally required in dish production.

Sweet Precision: The Technology Behind Chocolate Coating

Even the confectionery world benefits from technology.

Chocolates move along conveyor belts where they are evenly coated, cooled, and prepared for packaging.

The process is smooth, satisfying to watch, and ensures every treat is a perfect delight.