This step ensures the structure is ready for welding, highlighting the importance of precision in metal fabrication.

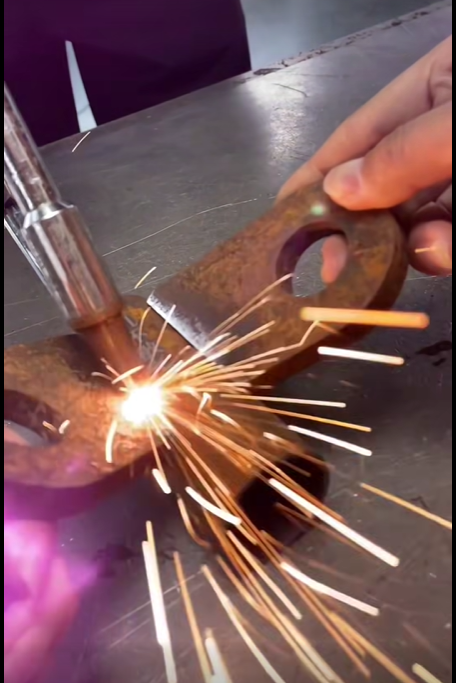

Igniting the Weld

With components securely in place, the welding torch is activated. Sparks fly as intense heat fuses the metal surfaces.

This moment captures the raw power and precision of welding, where steady hands and a focused arc are key to strong, clean joints.

Seamless Fusion Under Flame

The weld deepens as molten metal fills the seam, binding the materials into a unified, durable structure.

The consistent spark pattern shows expert technique, ensuring strength while minimizing defects like gaps or slag inclusions.

Metalwork on Unconventional Surfaces

Next, attention turns to a different material—a metal shovel. The welding torch slices through its reflective surface with precision.

This stage emphasizes how versatile cutting torches are, capable of modifying even curved or coated tools.

Clean Cutting with Controlled Sparks

As the sparks intensify, the torch cleanly cuts through the shovel’s metal.

This phase illustrates not just the effectiveness of the equipment but also the operator’s control in following a specific path, producing smooth edges ideal for reshaping or recycling.

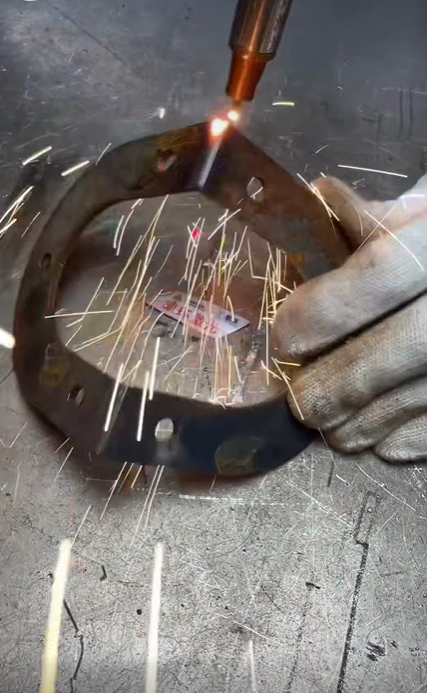

Shaping and Drilling Metal Rings

In the final image, a circular steel piece—possibly a flange or bracket—is held under a torch.

Sparks rain down as it is cut or modified, showcasing a crucial phase in manufacturing where parts are reshaped or refined to exact specifications.